Random Reflectance Analysis

Random Reflectance Analysis

16% off for the Fusinite Premium Members

Pricing Detail

Share

Tilgængelighed for afhentning kunne ikke indlæses

Please note: This product includes Random Reflectance Analysis only and does not provide full Intertinite content certification. For a complete Fusinite report and official certification, please order the Inertinite Benchmark (IBRo2) method, which combines Random Reflectance Analysis with reactive organic carbon quantification to accurately determine inertinite carbon content (dry basis, wt%). This standalone analysis is intended for research use only and is not valid for certification.

Beskrivelse

Random Reflectance Analysis

- Preparation of Polished Pellet: Each sample undergoes resin mounting, grinding, and polishing to create a scratch-free, mechanically polished surface, according to ISO 7404-2:2009, PN-EN 1860-2:2006, or PN-ISO 13909-4:2005 standards.

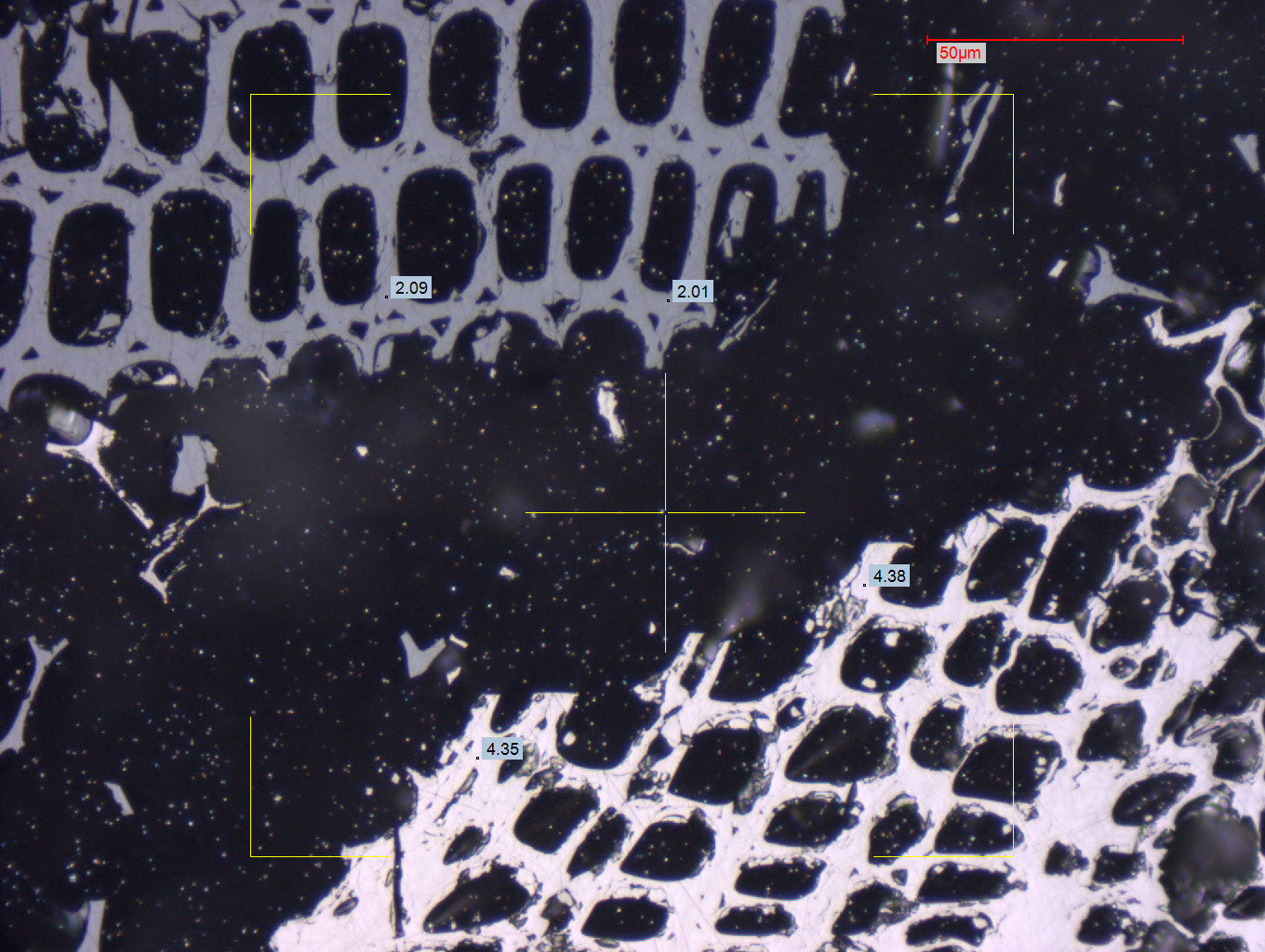

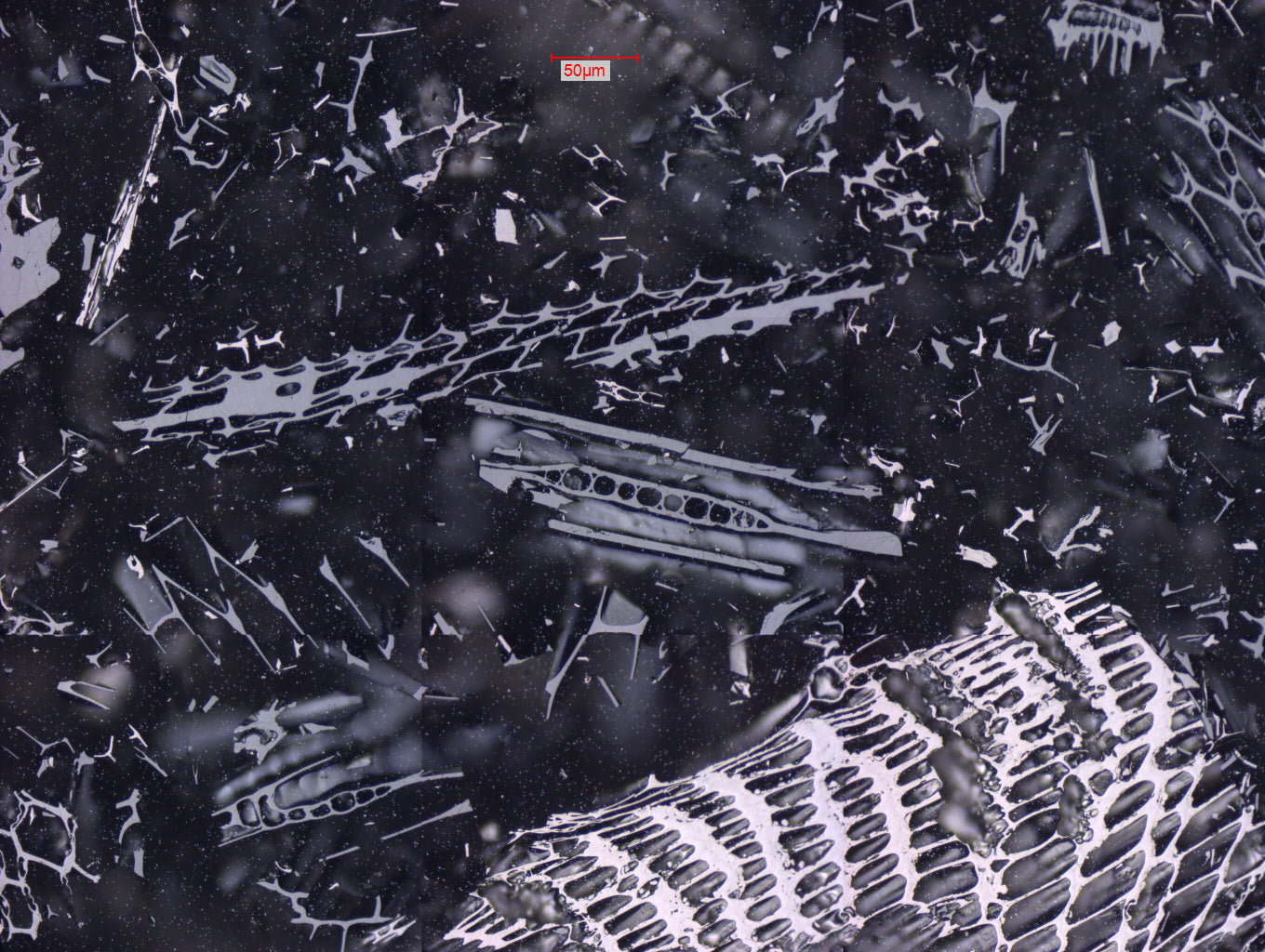

- Measurement of Mean Random Reflectance (Ro): We conduct 500 point measurements of reflected white light on the polished surface of biochar fragments, using an optical microscope (ISO 7404-5:2009).

- Volumetric Random Reflectance (Ro): By measuring the volume distribution of random reflectance across the biochar sample, we define the percentage of inertinite and semi-inertinite content (Sanei et al., 2024; ITPE Procedure and ISO 7404-5:2009).

Random Reflectance is the only rigorously calibrated empirical measurement of carbon permanence, grounded in decades of geological observations of sedimentary deposits. Unlike bulk value measurements, this method provides a spatial distribution of carbonization and carbon permanence across biochar particles in a single sample. In this analysis, the inertinite content of biochar is assessed by measuring the volumetric random reflectance (Ro) using optical microscopy with a photometry system. The fraction of biochar with Ro values exceeding 2%, known as the Inertinite Benchmark (IBRo2%), is identified as the permanently sequestered carbon on an ash-free, dry basis.

Furthermore, Ro enables the estimation of carbonization temperature (CT, °C) and its comparison with the pyrolysis production temperature (PT, °C), revealing any thermal inefficiencies during pyrolysis. Our report includes recommendations to optimize pyrolysis methods, aiming to enhance the homogeneity of the biochar and increase carbon stability.