Inertinite Benchmark Method (IBRo2) / Random Reflectance (Ro) - Analysis

Inertinite Benchmark Method (IBRo2) / Random Reflectance (Ro) - Analysis

16% off for the for Fusinite Premium Members

Including 60-min Free Virtual Consultation for each Shipment

Pricing Detail

Share

Не удалось загрузить сведения о доступности самовывоза

Описание

How it Works

Reporting Dashboard

This analytical package includes Random Reflectance (Ro) and molar H/C ratio measurements to quantify inertinite carbon content and assess biochar permanence. It includes a detailed digital interpretive report, digital verification, and certification, highlighting production efficacy and key quality indicators, including thermal diffusivity..

What’s Included:

1. Random Reflectance Analysis

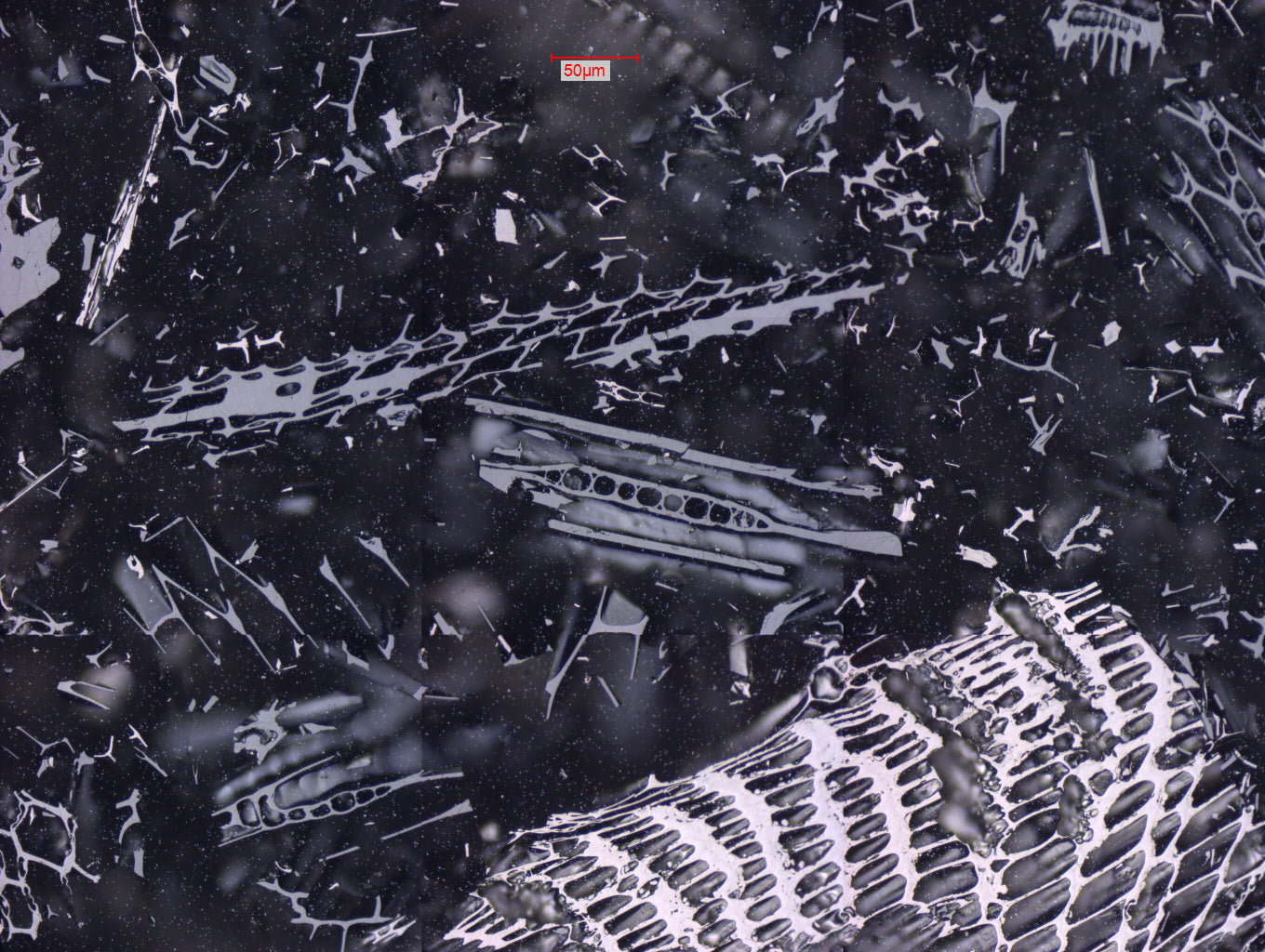

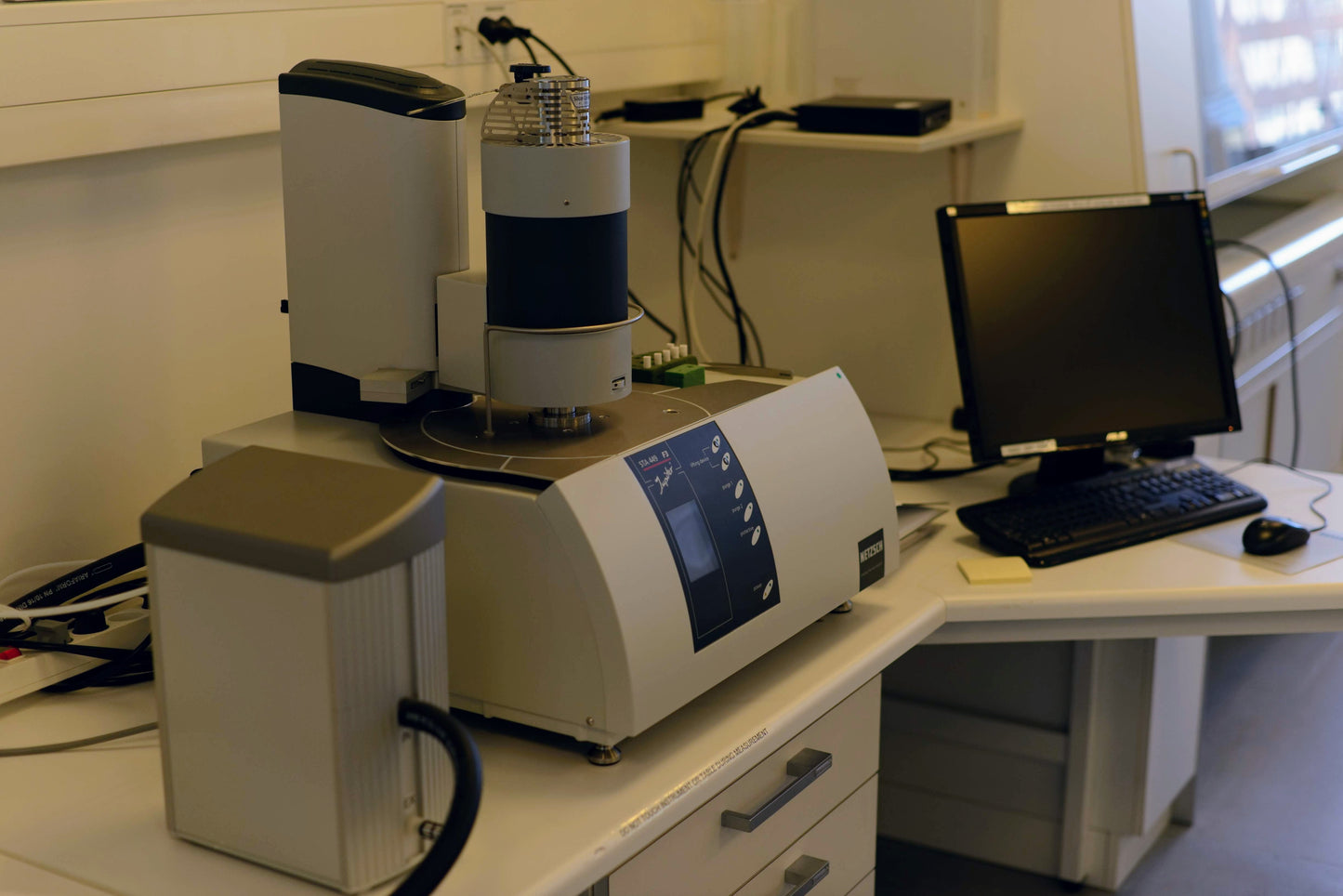

- Preparation of Polished Pellet: Each sample undergoes resin mounting, grinding, and polishing to create a scratch-free, mechanically polished surface, according to ISO 7404-2:2009, PN-EN 1860-2:2006, or PN-ISO 13909-4:2005 standards.

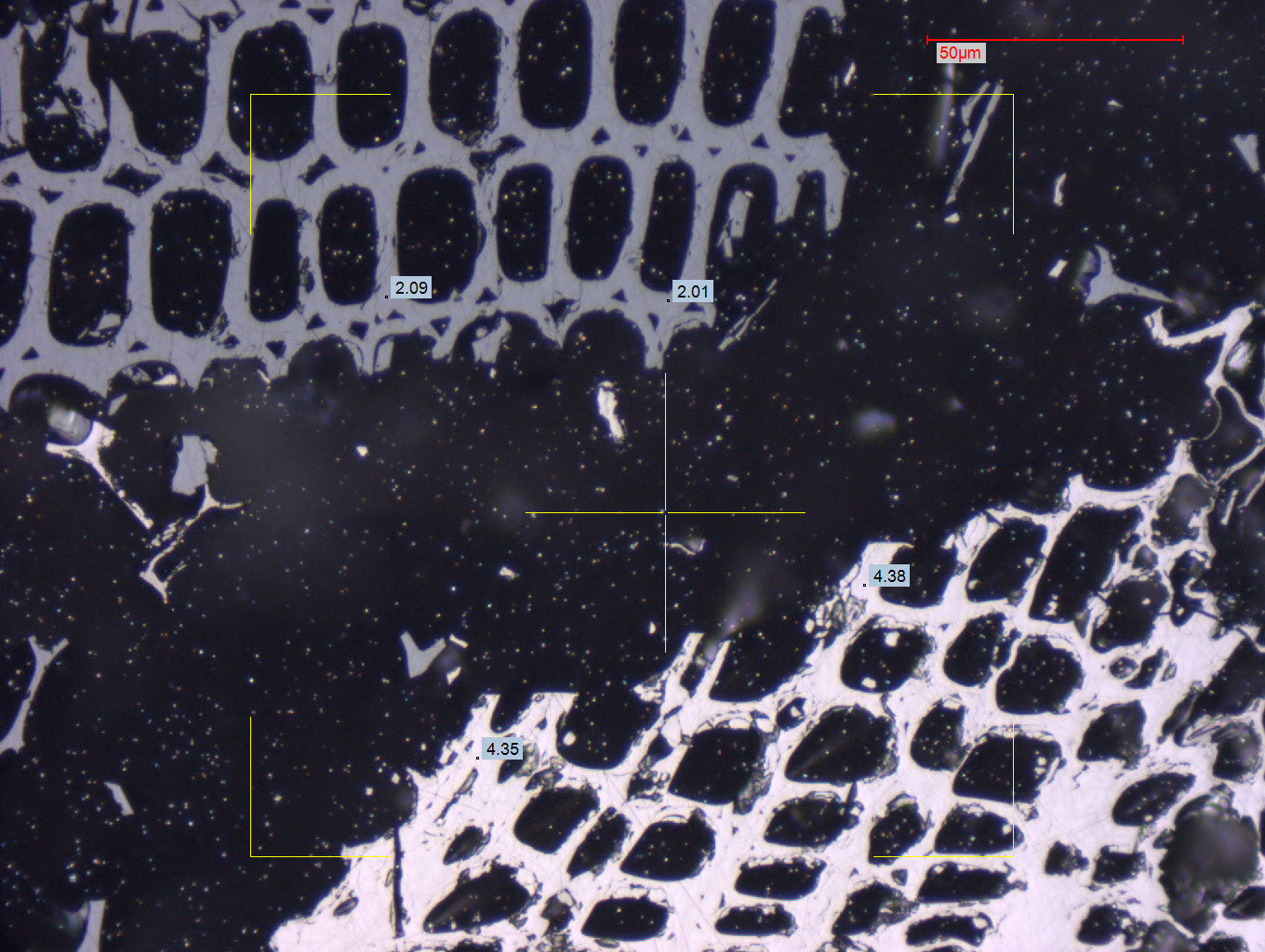

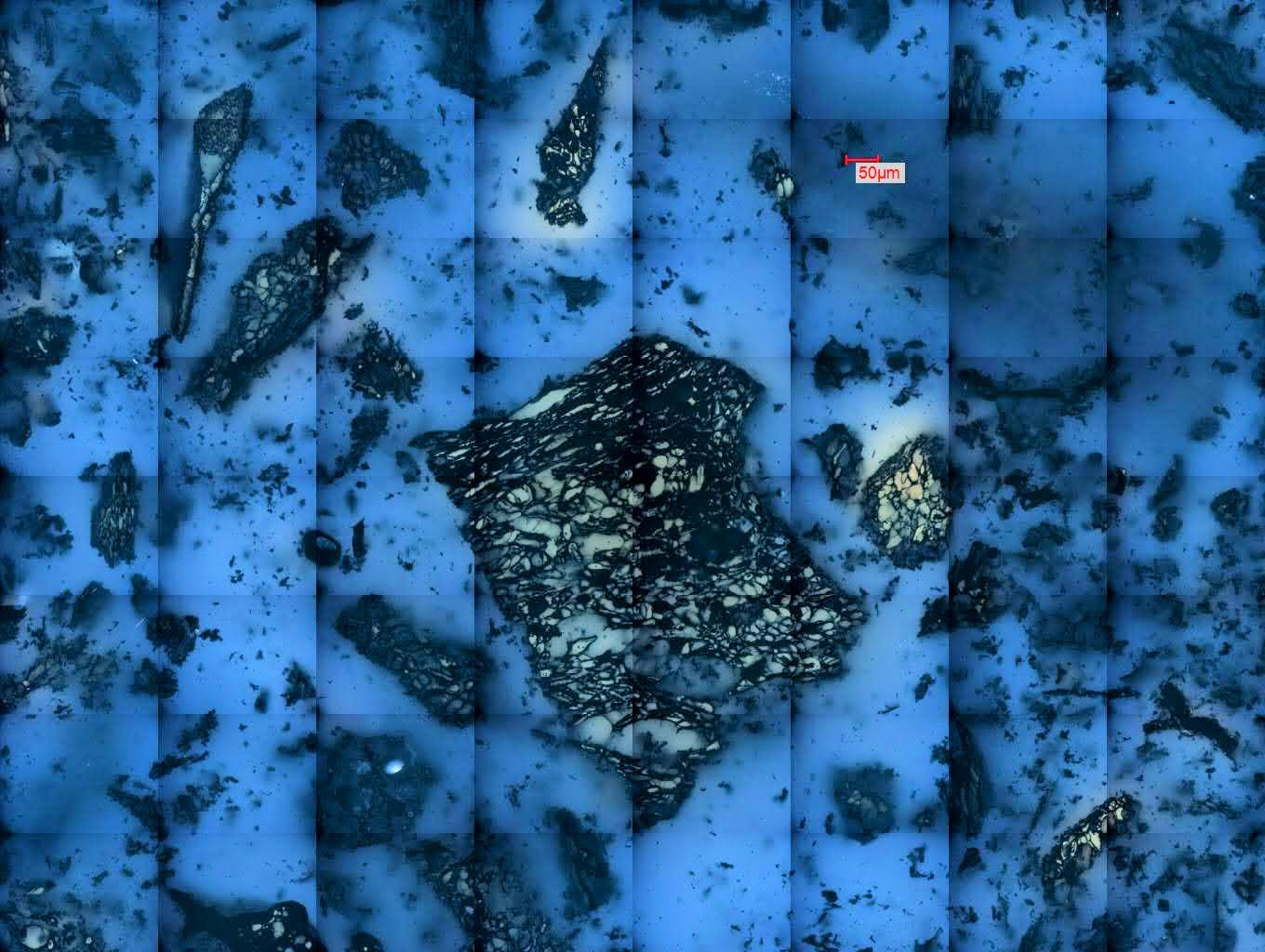

- Measurement of Mean Random Reflectance (Ro): We conduct 500 point measurements of reflected white light on the polished surface of biochar fragments, using an optical microscope (ISO 7404-5:2009).

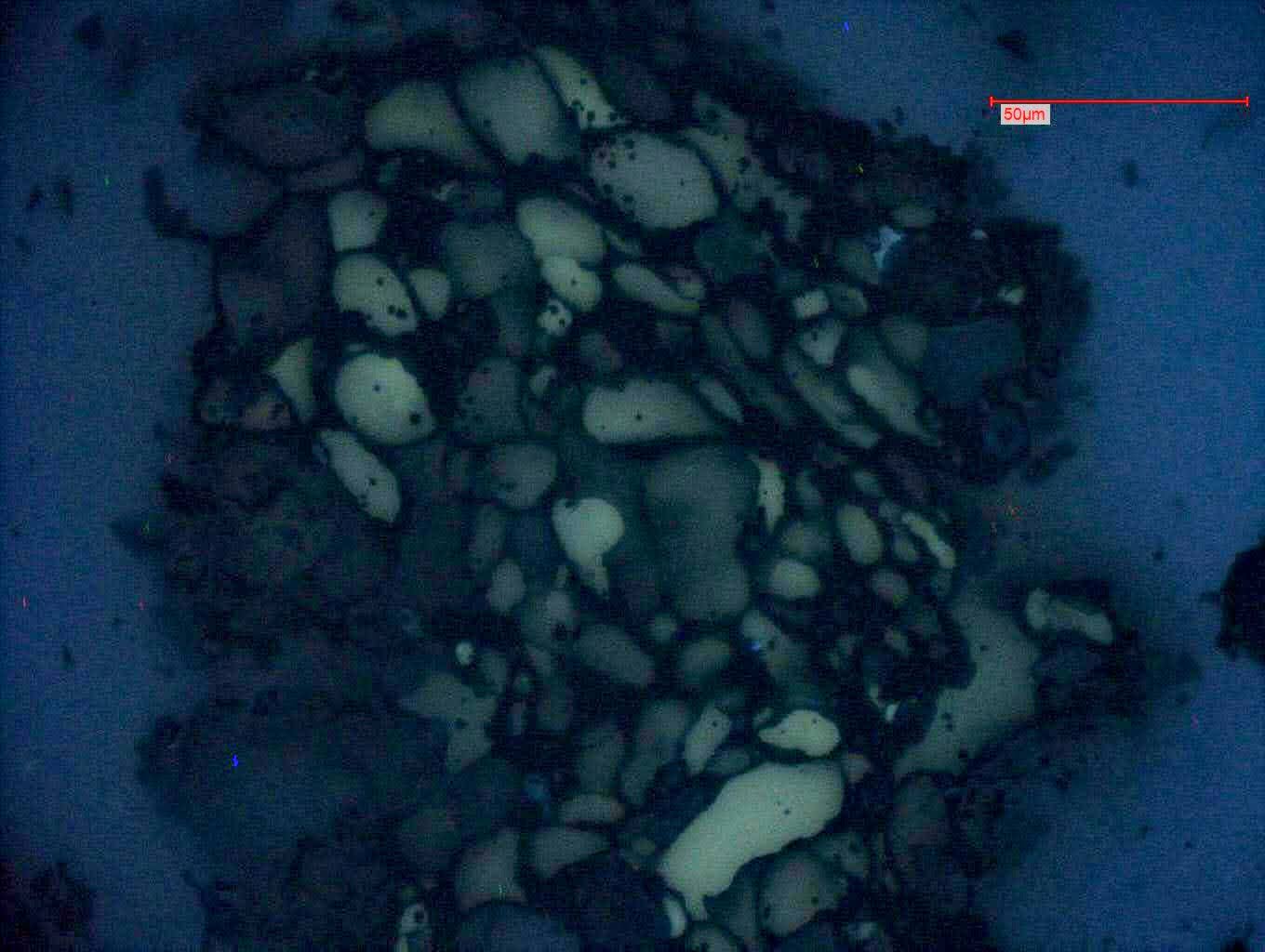

- Volumetric Random Reflectance (Ro): By measuring the volume distribution of random reflectance across the biochar sample, we define the percentage of inertinite and semi-inertinite content (Sanei et al., 2024; ITPE Procedure and ISO 7404-5:2009).

Random Reflectance is the only rigorously calibrated empirical measurement of carbon permanence, grounded in decades of geological observations of sedimentary deposits. Unlike bulk value measurements, this method provides a spatial distribution of carbonization and carbon permanence across biochar particles in a single sample. In this analysis, the inertinite content of biochar is assessed by measuring the volumetric random reflectance (Ro) using optical microscopy with a photometry system. The fraction of biochar with Ro values exceeding 2%, known as the Inertinite Benchmark (IBRo2%), is identified as the permanently sequestered carbon on an ash-free, dry basis.

Furthermore, Ro enables the estimation of carbonization temperature (CT, °C) and its comparison with the pyrolysis production temperature (PT, °C), revealing any thermal inefficiencies during pyrolysis. Our report includes recommendations to optimize pyrolysis methods, aiming to enhance the homogeneity of the biochar and increase carbon stability.

2. Elemental Analysis

- Carbon and Hydrogen Analysis (Dry Basis): We conduct Carbon (C) and Hydrogen (H) elemental analyses following ISO 29541:2010. This assessment, which includes a molar H/C ratio, is critical for evaluating biochar’s carbon sequestration potential and structural stability as well as its efficiency in carbonization.

3. Consultation

- 60-Minute Online Presentation and Consultation: Premium Members receive a personalized 60-minute online consultation to review the results in detail and discuss further applications.

- Place Your Order: Begin by placing your order for analysis through our intuitive online platform. Once you select your services, you will receive a shipping label to send your samples to the nearest research hub.

- Access to your reporting dashboard: Within 30 days, access the results of your latest shipment in your Fusinite client-specific dashboard. The dashboard provides detailed data, graphical representations, and recommendations. As you test more samples, your data will accumulate, creating a customized database to help improve your production and processes.

- Unlock the Inertinite Gold Certificate: Unlock your Intertinite Certificate for each qualified sample.

Certification & Market Integration:

Once your product is certified, your carbon storage security (CSS) credentials can be made available to buyers, regulators, and carbon creditors directly through our platform, allowing for seamless transactions in the voluntary carbon market.

Our Online Reporting Dashboard offers a powerful, user-friendly platform for managing and analyzing biochar sample data. Key features include:

- Customizable Plotting: Visualize multiple samples side-by-side with customizable plotting options, allowing you to compare key metrics like carbon stability, reflectance distributions, and carbon content.

- Interpretive Graphs: Generate in-depth interpretive graphs tailored to highlight trends, anomalies, and correlations across different biochar properties, helping you pinpoint production inefficiencies and optimize carbon stability.

- Sharable Reports: Easily share results and visualizations with colleagues or clients through secure, shareable links. Our dashboard also supports exporting reports in multiple

formats, so you can save or present findings conveniently. - Personalized Insights: The dashboard offers advanced options to customize data views and annotate results, making it ideal for deeper analysis and tailored recommendations.

This interactive tool provides a comprehensive, collaborative environment to assess and improve biochar quality, making data-driven decisions more accessible and efficient.